Solid-liquid separator

Company Introduction

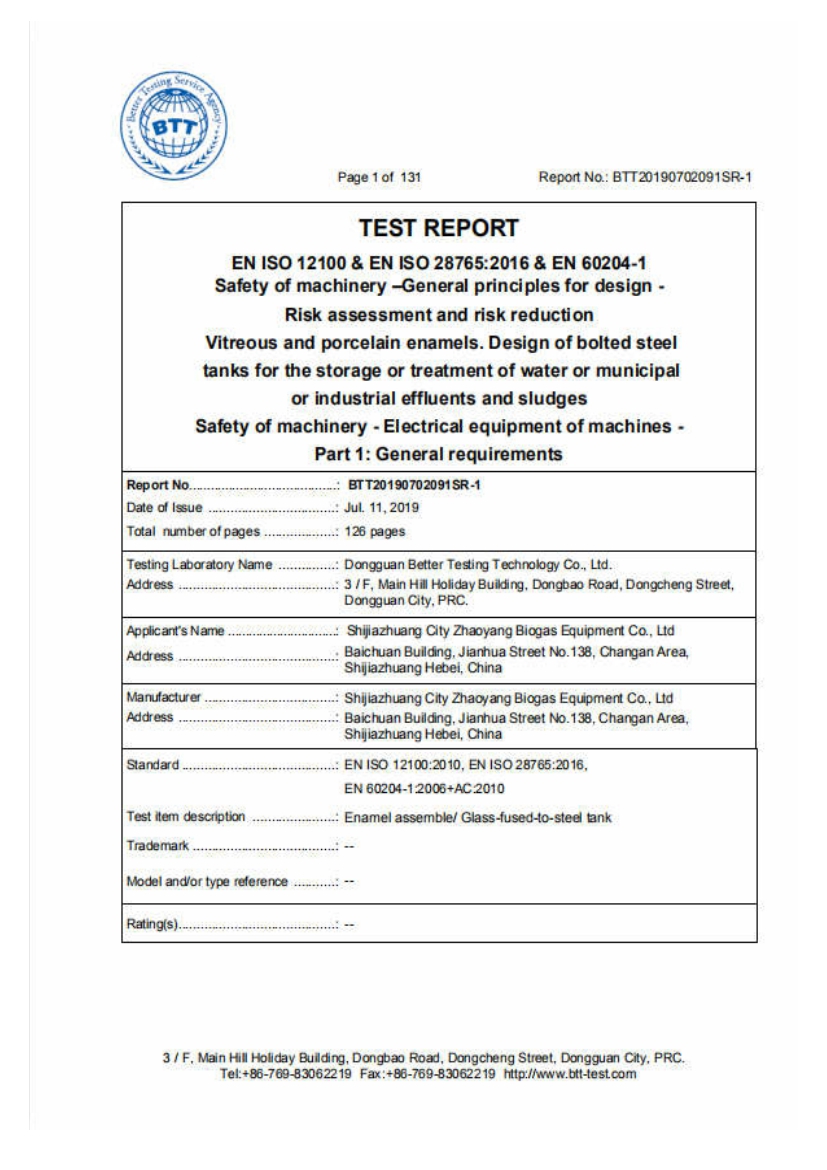

Establishment of Shijiazhuang Zhaoyang Biogas Equipment Co., Ltd. in April 2009, Established on 2017, Boselan Tanks CO.,LTD . Branch company focusing on international trade.

Our company is a member of China biogas society, a member of Shanghai rural energy industry association, and a member of Hebei rural energy association. It is a modern enterprise that takes the biogas equipment industry as the leading industry, devotes itself to the development of energy saving and environmental protection biogas products, and takes creating high-quality and famous brand as its own responsibility.

Our company is a large, medium and small methane engineering supporting anaerobic tank system, gas storage system, purification system, gas transmission system.My company's flagship product for enamel assembled jar, biogas double membrane gas holder system, roof, side mixer, methane control constant pressure regulator gas supply system, biogas desulfurization tower, gas dehydrator, firedamp flame arrester, biogas condenser, feces, renewal biogas slurry solid liquid separator, the gas torch, biogas residue pump, marsh gas flowmeter, fertilizer equipment, some products have been national patents.

About It

Introduction: spiral extrusion type solid-liquid separator is mainly composed of main engine, non-clogging pump, control cabinet, pipeline and other equipment.The parts of host organism, mesh screen, extrusion stranding, vibration motor, deceleration motor, weight, unloading device.Its working process is as follows: non-clog pump without fermentation slurry pump into the body, the motor speed blanking, under the action of the power transmission, squeezing ground dragon will waste water gathering toward the body forward, at the same time improve the pressure of the front, forcing the moisture in the material in the side pressure under the action of belt filter mesh and its outflow drainage pipes.The work of the extruder is continuous, its material is constantly pumped into the body, the pressure of the leading edge is constantly increasing, when to a certain extent, the discharge port will be pushed open, extrusion extrusion port, to achieve the purpose of extrusion out.The filtered waste water flows away from the lower end of the solid-liquid separator and the separated solid material is discharged from the front end of the solid-liquid separator.

Contact

WeChat/Whatsapp: +8613754519373