Clarifier Tank

Company Introduction

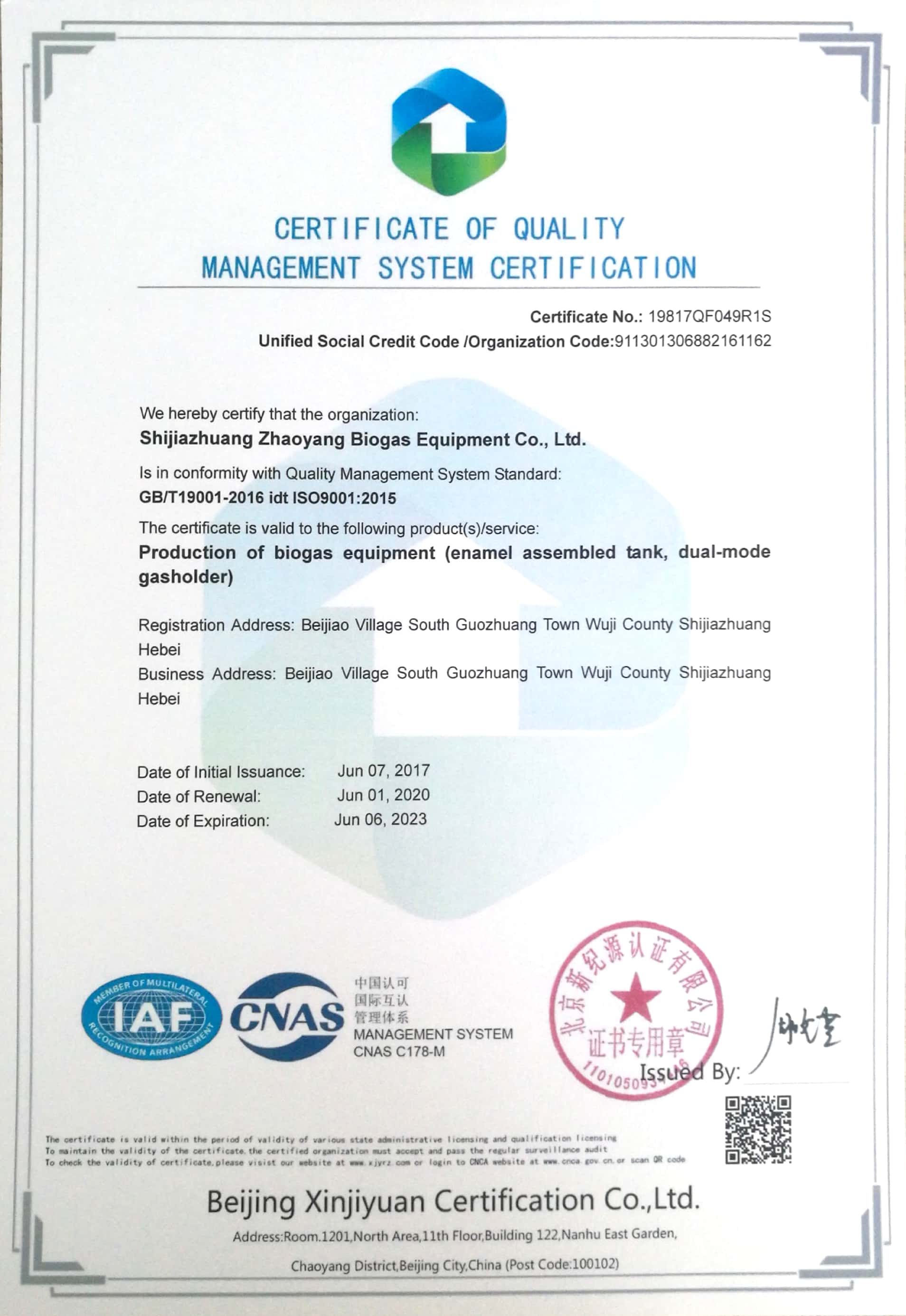

Establishment of Shijiazhuang Zhaoyang Biogas Equipment Co., Ltd. in April 2009, Established on 2017, Boselan Tanks CO.,LTD . Branch company focusing on international trade.

Our company is a member of China biogas society, a member of Shanghai rural energy industry association, and a member of Hebei rural energy association. It is a modern enterprise that takes the biogas equipment industry as the leading industry, devotes itself to the development of energy saving and environmental protection biogas products, and takes creating high-quality and famous brand as its own responsibility.

Our company is a large, medium and small methane engineering supporting anaerobic tank system, gas storage system, purification system, gas transmission system.My company's flagship product for enamel assembled jar, biogas double membrane gas holder system, roof, side mixer, methane control constant pressure regulator gas supply system, biogas desulfurization tower, gas dehydrator, firedamp flame arrester, biogas condenser, feces, renewal biogas slurry solid liquid separator, the gas torch, biogas residue pump, marsh gas flowmeter, fertilizer equipment, some products have been national patents.

About It

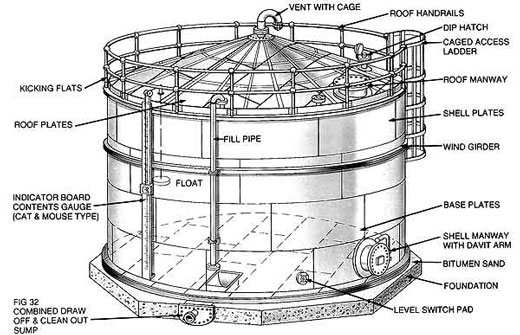

Clarifier tank, clarifier tank is the application of precipitation removal of suspended matter in the water of a structure, water purification equipment.Remove suspended matter from the water by natural precipitation or coagulation precipitation.The clarifier tank is divided into horizontal clarifier tank and vertical clarifier tank according to the direction of water flow.The GFS tank can well meet this demand, and the installation cost is higher than the cement tank bottom, and the transportation cost is higher than the fiberglass tank bottom, which is the hot product in the sewage plant construction and the first choice of many customers.

GFS Tank

Enamel technology is the most advanced technology in the tank Market. GFS tank is made of high-strength titanium alloy steel plate as the base material. Through professional double-sided enamel technology, the metal surface is covered with an inert glaze layer to achieve the purpose of high toughness and super corrosion resistance. It has all-round advantages after being spliced into cans by spiral.

Advantages

Convenient installation and short construction period.

Low maintenance cost and long service life.

The construction is flexible, expandable and recyclable.

Modular installation, high added value, high standard.

Controllable quality, suitable for different climate.

Industrial production, beautiful appearance, superior quality.

Edge Enameled Technology

Boselan tank's edges coated with the same enameled material in order to avoid electrolysis of dissimilar metals, rust and weakening of the enameled bonding.

Standard Enamel Steel Plate Specification

|

Volume ( m3 ) |

Diameter ( m ) |

Height ( m ) |

Floors ( layer ) |

Total Plate Number |

|

511 |

6.11 |

18 |

15 |

116 |

|

670 |

6.88 |

18 |

15 |

135 |

|

881 |

7.64 |

19.2 |

16 |

160 |

|

993 |

14.51 |

6 |

5 |

95 |

|

1110 |

9.17 |

16.8 |

14 |

168 |

|

1425 |

13.75 |

9.6 |

8 |

144 |

|

1979 |

15.28 |

10.8 |

9 |

180 |

|

2424 |

16.04 |

12 |

10 |

210 |

|

2908 |

17.57 |

12 |

10 |

230 |

After sales service

GFS tanks can provide 30 years’ service life span almost without any maintenance in daily operation. Furthermore, BSL tanks promise 1 year’s quality warranty for all the tanks once finish the installation. This is our commitment to all customers.

Design Drawing

Contact

WeChat/Whatsapp: +8613754519373